Milla Automotive was founded in 2014 with the aim of being a preferred company in the sector with Engineering and Mold Production. Milla Automotive is a partner of Family group with Milla Yapı and Milla Bölme . 2014 Milla Otomotiv was founded Starting with Enginering and Mold Manufacturing with an area 100 m ² workshop 2017 Moved new workshop with an area 800 m ². Bought two 120 T plastic injection machines and started plastic part production 2018 Workshop area became 1.750 m ² by adding next and cross workshops . Added new 320 T injection machine 2019 Bought 3 Engel injection machines with two 500 T and 700 T 2024 Will be moved new plant with an area 4.250 m ² in Nilüfer Indsutrial Zone

Exterior plastic parts are developed by BMC and MİLLA together as Co-Designer. Part design, tool design, tool production, plastic injection oroduction and assembly is applicated under MİLLA responsibility with expertized engineers.

Interior plastic parts are developed by BMC and MİLLA together as Co-Designer. Part design, tool design, tool production, plastic injection oroduction and assembly is applicated under MİLLA responsibility with expertized engineers.

The Altay tank is a modern main battle tank designed to maximize crew safety. In this context, the escape hatches integrated on the vehicle play a critical role in ensuring life safety in emergency situations. The escape hatches are manufactured by MİLLA. Technical Features • It has an armored structure; maintains ballistic resistance against external threats. • It can be easily opened from the inside with the help of a mechanical arm; it is designed for emergency evacuation. • It allows the crew to be evacuated through 3 different exit points when necessary.

The transport case of the military personnel transport vehicle is manufactured from high-strength steel to ensure the safe transfer of personnel in the operational field of armored units. The manufacturing process was carried out by MİLLA as seen in the following steps. • Ballistic-resistant steel plates are cut to the desired tolerances on CNC laser/plasma machines, then press-bend is applied. • The parts are joined using MIG/MAG welding techniques; the weld seams are checked with non-destructive testing (NDT). • Assembly and Integration: The body is assembled on the chassis; covers, seating units and personnel equipment are added. • Functional Tests: Mechanical suitability, sealing and static load tests are performed.

The Altay main battle tank meets the requirements of modern battlefields not only with its superior firepower and armor protection, but also with its ease of maintenance and logistics. Maintenance hatches placed in different areas of the tank play a critical role for both rapid intervention and regular maintenance. The machining, shaping, welding and assembly processes of the basic maintenance hatches in the Altay tank were carried out by MİLLA.

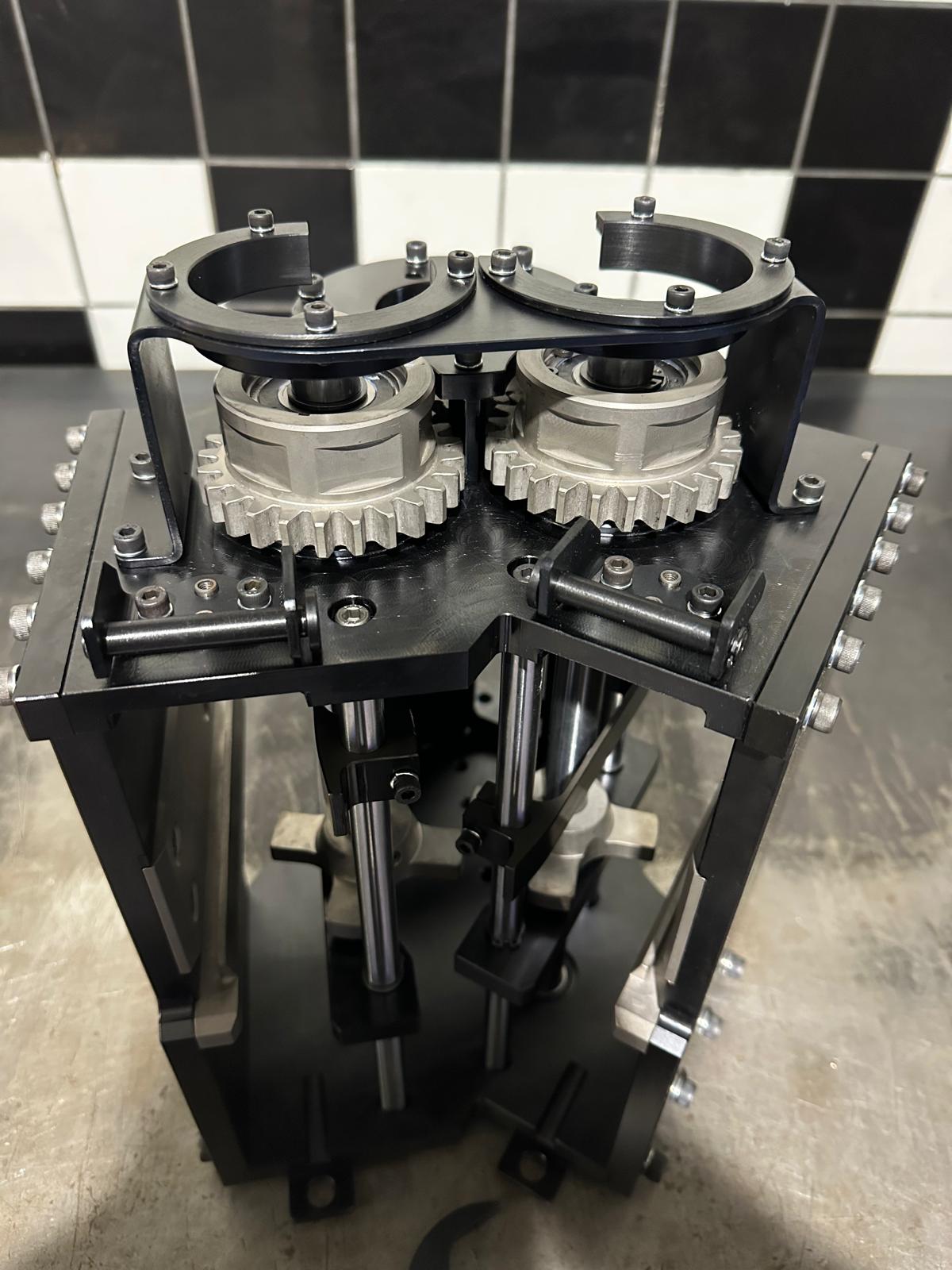

25mm simulator mechanism used for the main weapon ammunition feeding system in the medium caliber modular turret of the ALTAY tank.

Portable Air Defense Missile System (PADMS); is a portable, single-person shoulder-fired air defense missile system to be used in short-range air defense of mobile/fixed units and facilities in the battlefield and rear area. The trigger assembly of the Missile System, made of special engineering plastics resistant to high temperature and strength, is produced by MİLLA for ROKETSAN, along with all other sub-parts.

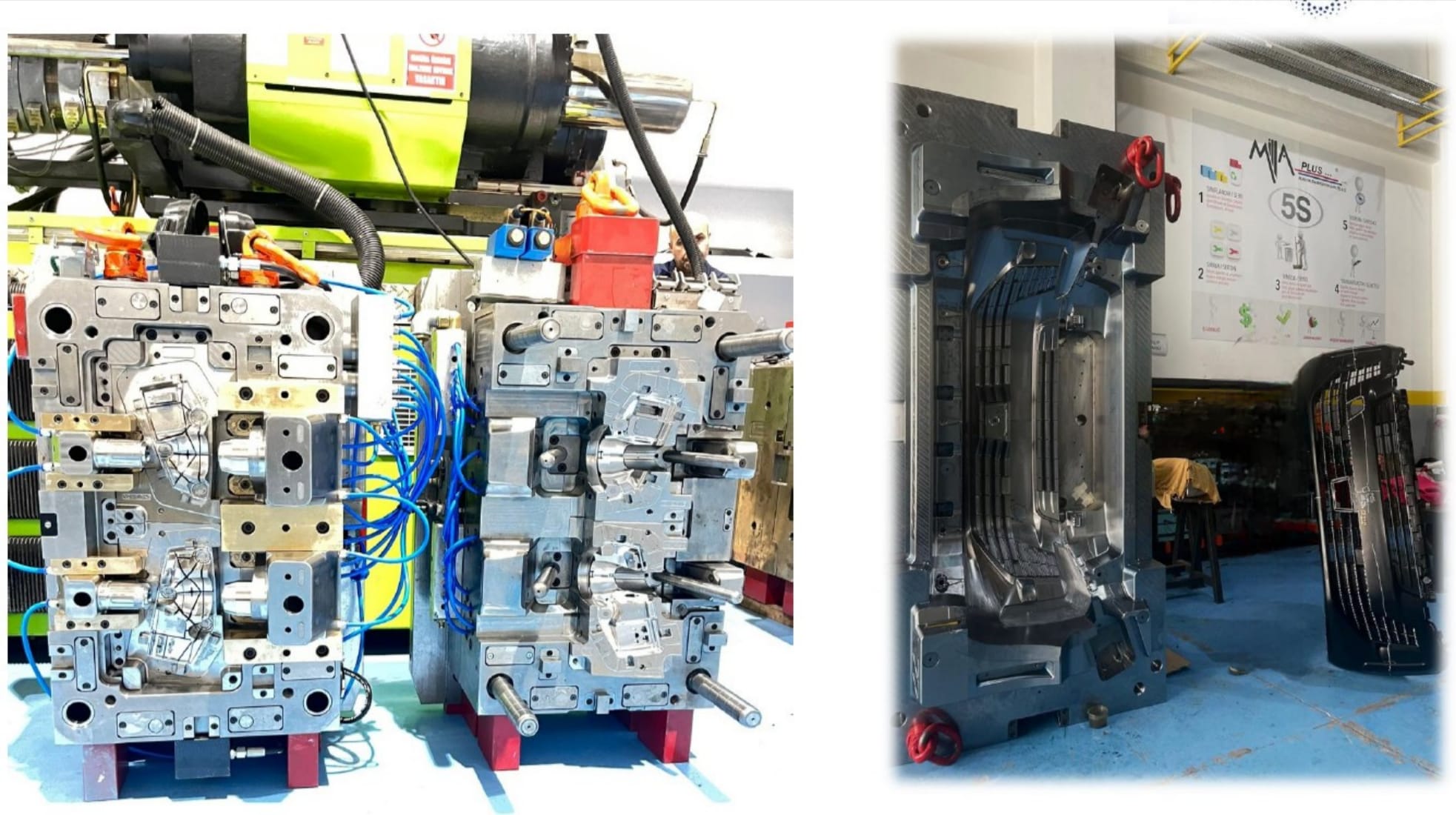

At MİLLA, molds containing high technology and engineering solutions in different sizes for use in plastic injection manufacturing with raw materials such as ABS, PA, PP, TPE, PBT, POM, PC, ASA are designed and produced according to customer expectations and specific requirements for defence and automotive industry.